Among its various productions, IFT deals with making plastic equipment for the dairy sector, which are used by the most important dairies worldwide with great satisfaction. The wide range of IFT products gives innovative, practical and intelligent solutions to all producers of various types of cheese: asiago, montasio, dairy, monte veronese, raschera, formai de mut, toma, grana padano, parmigiano reggiano, pecorino toscano, pecorino Roman, Sardinian pecorino, caciotta, goudha, goat cheese, gorgonzola, taleggio, fontina, fontal and many more.

Through a long experience in the sector, the company is able to propose high efficiency food technologies for the dairy sector. In fact, the dairies that use IFT equipment and solutions comply with the strictest national and international regulations in terms of safety and hygiene of products in contact with food, managing to standardize their cheeses (all first choice) and obtaining advantages concerning the following aspects:

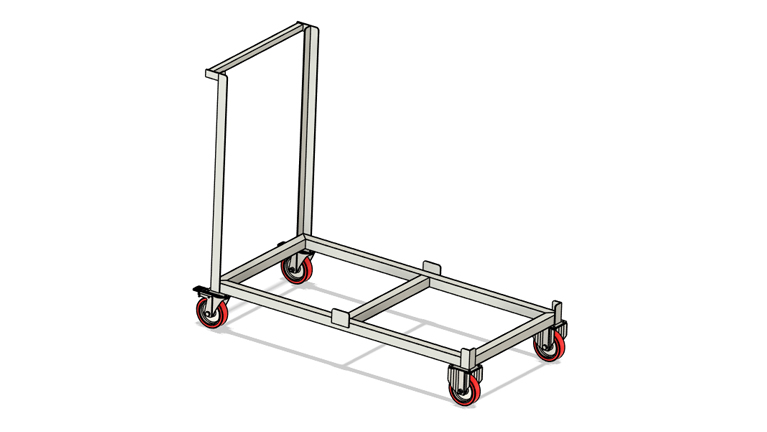

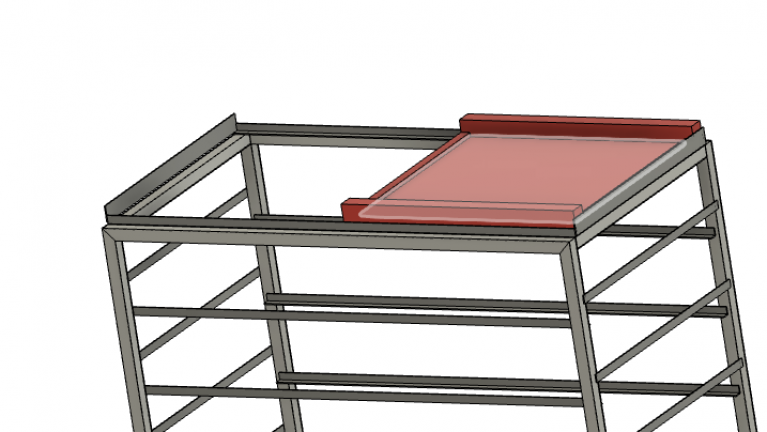

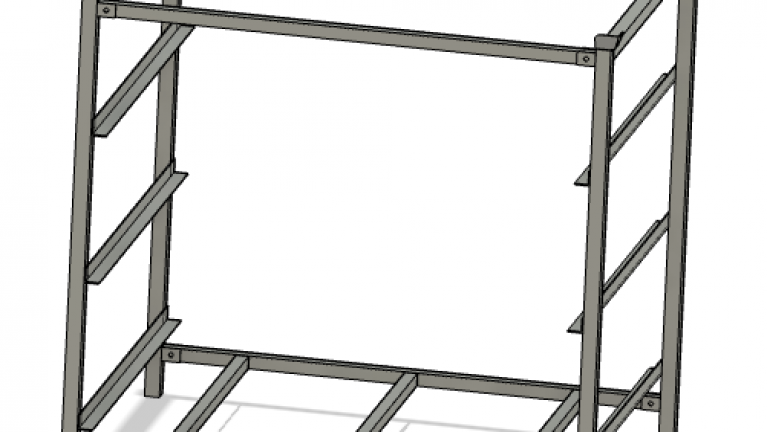

In order to meet the different needs of each client, IFT is responsible for creating a wide range of plastic equipment for the dairy sector. Specifically, in fact, the company can produce the following types of technologies for this sector:

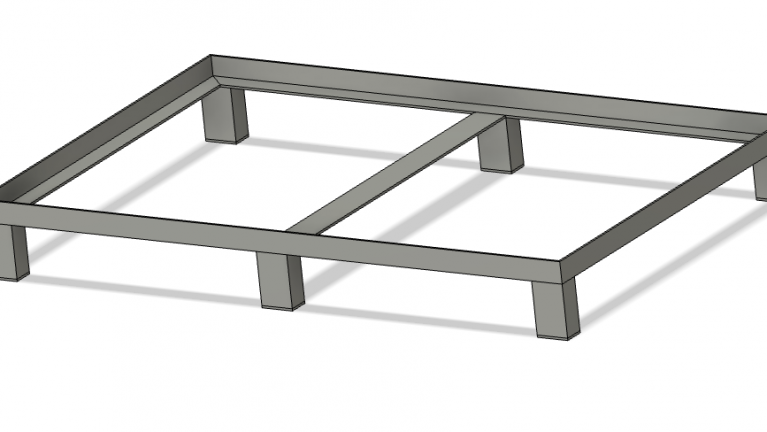

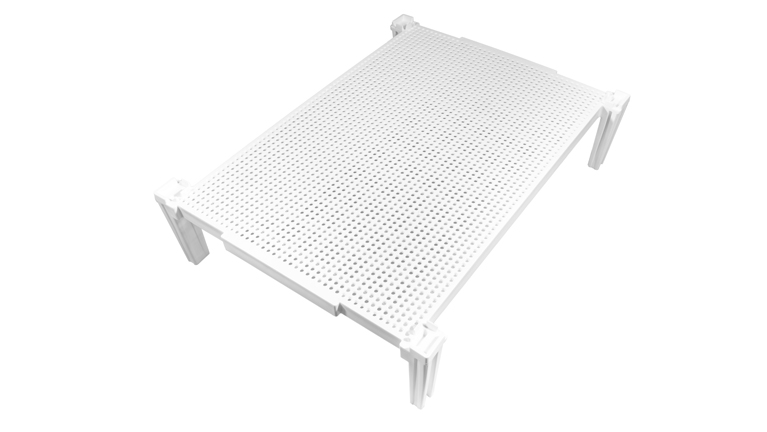

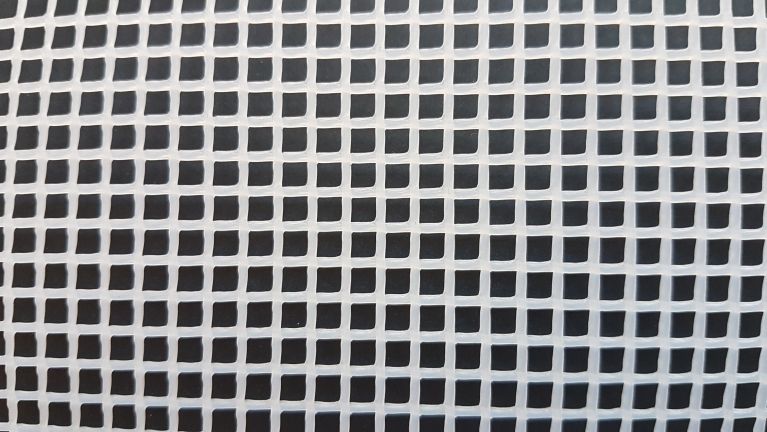

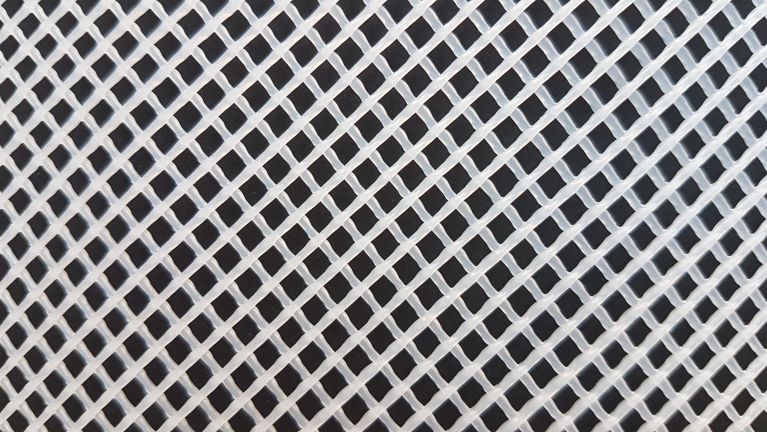

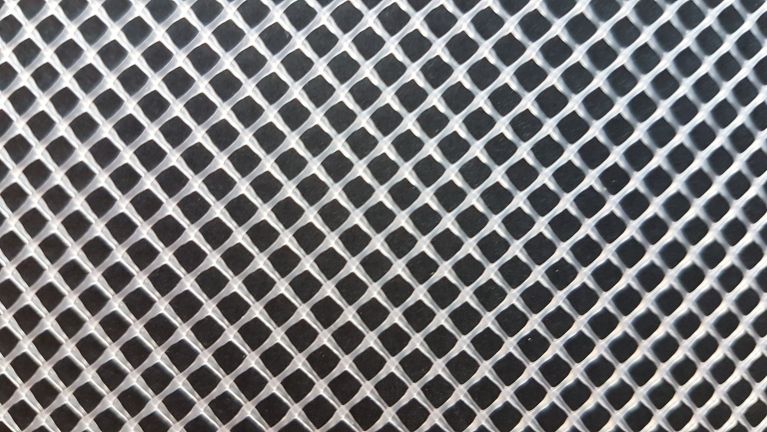

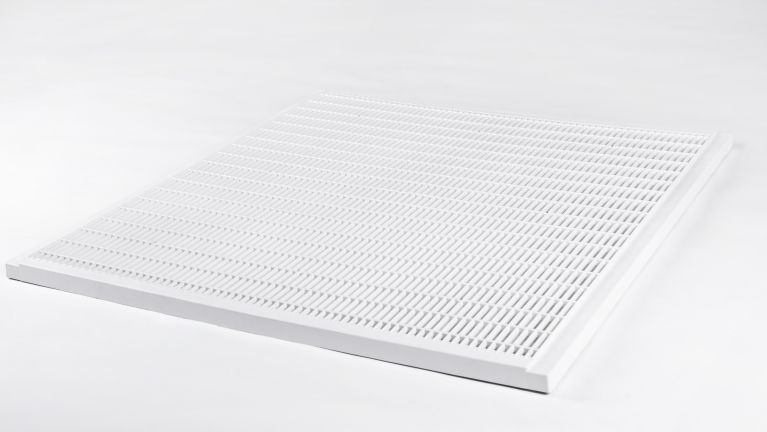

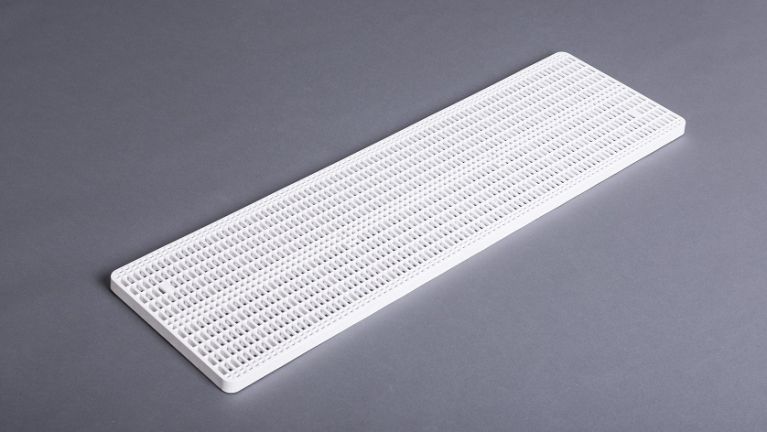

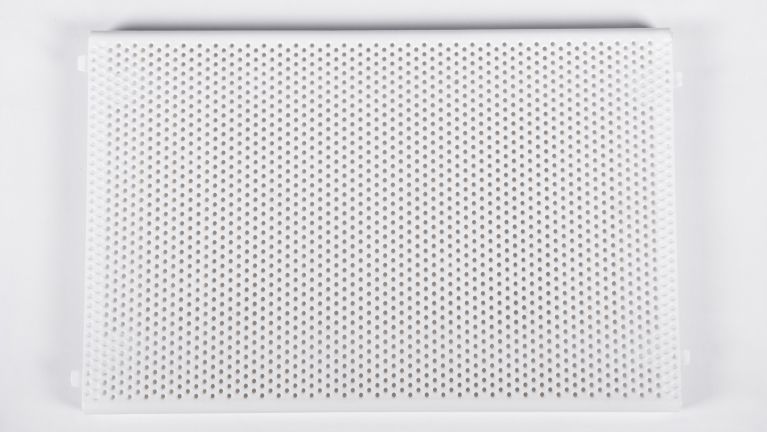

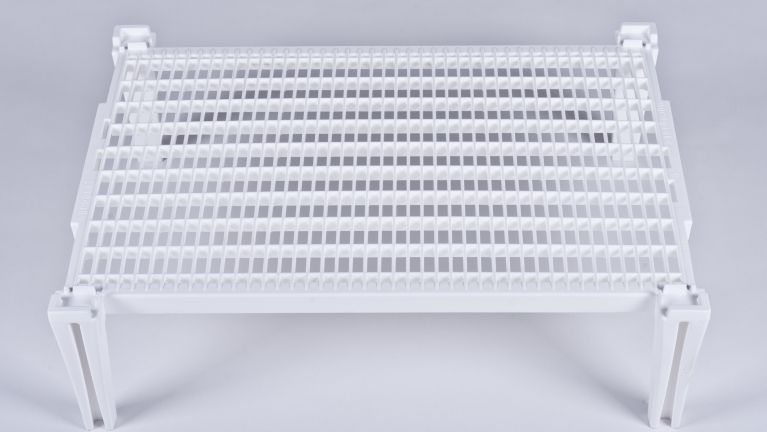

The measures are varied for each type of dairy, maturing and the technical staff will always be able to find the best solutions for all dairies. In addition, one of the most popular products by IFT customers in the dairy sector is the stackable food-grade polypropylene grid according to CE standards, as it is an extremely comfortable, hygienic, practical and very robust item. With this equipment IFT is replacing and surpassing the market of similar stainless steel grills that, despite being good products, are very delicate and tend to deteriorate after a few years. The IFT PP grids instead maintain the same characteristics of concept and application of the stainless steel grilles, but with the advantage of being injection molded in one piece, of not having soldering points, of not having other problems typical of stainless steel grids, such as the desoldering of the rods, the folding of the feet, the risk that the operators cut their hands or that after a few years do not stack anymore. The IFT PP grids are really very strong and an exceptional product and, unlike the stainless steel grids, even the plasticizing of the cheeses is not sticky on them: during the washings, even those who plastify the cheese on the stainless steel grills have the problem that the plasticizing it is not completely washed away and the traces left stain the cheese. On IFT products, however, this does not happen: they are washed and sanitized perfectly with a pressure washer, in the washing tunnels and also in the lava molds.